|

|

In this issue:

• 3D Printing a Hypercar

• Sensor Tip: Analog Outputs for Position Sensors

• Application: Controlling Food Dimensions

• and more

To view newsletter in your browser click here.

Featured video: Czinger 21C 3D-printed hypercar

|

|

|

|

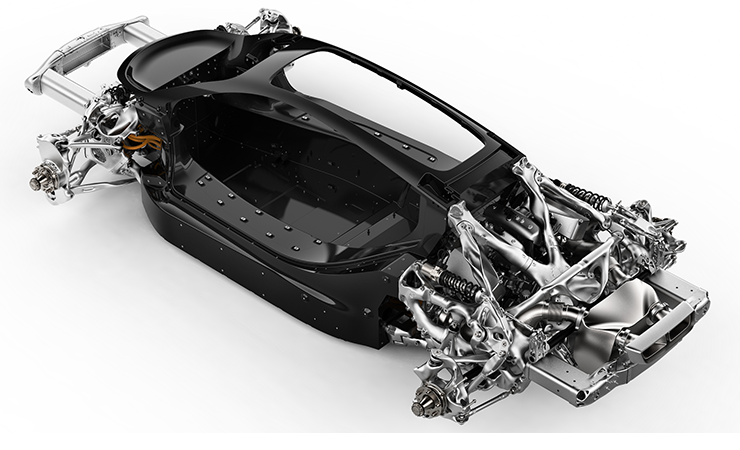

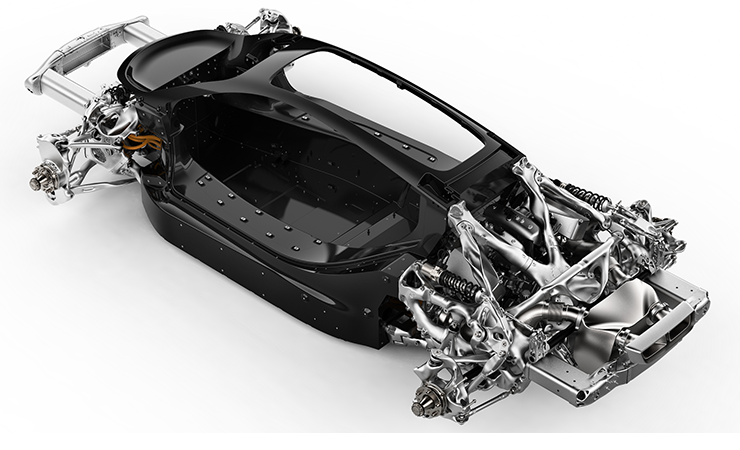

3D Printing Much of a Record-Setting Hypercar |

|

". . . Not only does it deliver industry leading performance in every metric, but it also embodies a technology that will fundamentally change the automotive industry—it is a

historically significant vehicle."

—Lukas Czinger, Co-Founder

With a claim like that, you wonder what do they have to back it up? Let's see.

According to Czinger company, they apply some leading edge technology to the

design and build processes of the cars they make. This includes using super computers

with their own custom software platform and artificial intelligence software and a

generative design process for the chassis.

If you're unfamiliar, generative design leverages the power of 3D printing parts to enable

an affordable iterative process in which the designer makes judgements of the parts

produced, then adjusts the programming to optimize the design of a particular part. The

optimization could minimize trade-offs of part strength, weight, durability, cost and other

factors.

Regarding the chassis of Czinger cars, the website states they created patented alloys,

and quoting from the Czinger website, "each printed component is assembled into the final structure

using high-accuracy laser guided robotics."

But what about performance? Breaking the Laguna Seca Raceway record last year by enough to call it "smashing" is an incredible start. Powering that performance is a hybrid propulsion system consisting of a twin-turbo flat-plane V8 internal combustion engine and twin electric motors. These combine to produce up to 1,350 hp according to Czinger. See the Laguna Seca lap record.

Sources:

1) https://www.czinger.com

2) https://www.youtube.com/watch?v=8ybNkgC0eHY

|

|

|

|

| Key Points On Current and Voltage Sensor Outputs |

Analog interfaces are an obvious choice for design engineers needing to connect a

position or angle sensor with a pre-selected control device that accepts standard current

and/or voltage inputs such as a signal conditioner. Position sensors are generally

available with one of three analog outputs: percentage of supply, defined voltage and

defined current outputs.

A voltage output option that is a percentage of supply voltage, say 10 to 90% of a 10 V

supply would result in a sensor output range 1.0 to 9.0 V full range.

An example of a defined voltage range output, independent of a 24 V supply, could be

stated as a 0 to 10 V output range representing 0 to full scale of stroke length (or

angular range). The actual usable range must be a small minimum voltage e.g. 0.2 V,

making the actual output range 0.2 to 10 V. This output is sometimes available with a

decreasing value representing an increasing value in stroke or angle. In that case, +10

to 0 V could represent, for example, 0 to +100 mm change in stroke position. An example of a defined voltage range output, independent of a 24 V supply, could be

stated as a 0 to 10 V output range representing 0 to full scale of stroke length (or

angular range). The actual usable range must be a small minimum voltage e.g. 0.2 V,

making the actual output range 0.2 to 10 V. This output is sometimes available with a

decreasing value representing an increasing value in stroke or angle. In that case, +10

to 0 V could represent, for example, 0 to +100 mm change in stroke position.

There are generally two defined current output ranges. These are 0 to 20 mA and 4 to

20 mA. These current values represent a minimum to maximum stroke range or angular

range.

The advantage of using a sensor with a 4 to 20 mA output is that it inherently indicates

an open/broken lead fault when the output signal falls to 0 mA, which is below the 4 mA

minimum normal signal range expected. This can be monitored by a PLC and alert

users.

Voltage output sensors are quick and easy to implement as most PLCs have modules

accepting a voltage input. Sensors with current outputs are used for longer cable runs

and where electrical noise is present in the environment, as current is inherently

unaffected by noise and its level is sustainable over a long cable run with a sufficiently

sized conductor wire gauge. Voltage output sensors are quick and easy to implement as most PLCs have modules

accepting a voltage input. Sensors with current outputs are used for longer cable runs

and where electrical noise is present in the environment, as current is inherently

unaffected by noise and its level is sustainable over a long cable run with a sufficiently

sized conductor wire gauge.

In general long cable runs may need special consideration as voltage will drop with a

long enough run and the length of the run can dictate the wire size with larger diameter

wire needed for very long runs.

|

|

Controlling Food Dimensions |

|

|

It may seem simple to bake some cookies, but if you’re producing commercial volumes

of cookies for sale in far-flung markets, consistency of the product is very important. In

order to control the thickness of machine-produced cookies two position sensors, 25

mm and 50 mm TEX Series linear position sensors are used at either end of a swing

roller on a conveyer system as part of a cookie and biscuit baking machine. The

sensors are a part of the control system for thickness of cookies and biscuits for a major

food processing company..

Link to more information: https://www.novotechnik.com/tex

|

|

| |

|

|

Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor

|

|

An example of a defined voltage range output, independent of a 24 V supply, could be

stated as a 0 to 10 V output range representing 0 to full scale of stroke length (or

angular range). The actual usable range must be a small minimum voltage e.g. 0.2 V,

making the actual output range 0.2 to 10 V. This output is sometimes available with a

decreasing value representing an increasing value in stroke or angle. In that case, +10

to 0 V could represent, for example, 0 to +100 mm change in stroke position.

An example of a defined voltage range output, independent of a 24 V supply, could be

stated as a 0 to 10 V output range representing 0 to full scale of stroke length (or

angular range). The actual usable range must be a small minimum voltage e.g. 0.2 V,

making the actual output range 0.2 to 10 V. This output is sometimes available with a

decreasing value representing an increasing value in stroke or angle. In that case, +10

to 0 V could represent, for example, 0 to +100 mm change in stroke position. Voltage output sensors are quick and easy to implement as most PLCs have modules

accepting a voltage input. Sensors with current outputs are used for longer cable runs

and where electrical noise is present in the environment, as current is inherently

unaffected by noise and its level is sustainable over a long cable run with a sufficiently

sized conductor wire gauge.

Voltage output sensors are quick and easy to implement as most PLCs have modules

accepting a voltage input. Sensors with current outputs are used for longer cable runs

and where electrical noise is present in the environment, as current is inherently

unaffected by noise and its level is sustainable over a long cable run with a sufficiently

sized conductor wire gauge.