|

According to the Fluke corporation, "excessive vibration is one of the leading causes of machine failure." While Fluke and other companies in their category tend to focus on vibration analysis and some recommendations, we wanted to add designing-in prevention to the mix.

Some causes we have seen listed for vibration-related machine failures include unbalanced weight about a rotating part, thermal expansion of some parts, bearing that are either worn, over- or under-lubricated, machine resonance, loose parts and improper reassembly after maintenance.

Attention to these areas and machine vibration damping products could reduce vibration and problems associated with it. Another level of prevention can be reached by design engineers specifying in-motion parts that are designed to handle relatively high levels of shock and vibration.

Let's first define our terms. Shock is an impulse of energy applied to a machine or system. This causes sudden acceleration. Being an impulse, the duration of a shock event is short, but its amplitude can be large. Vibration is defined as mechanical oscillations that occur around a center-point.

According to sources of research, gearboxes, compressors, electric motors, fans, pumps, and blowers can create vibration in the range of 0.2 to 15 g of overall peak acceleration from 0 to 5,000 Hz. In a number of cases, a "damage factor" can be reliably used to predict future machine failure instead of conventional vibration monitoring. A particular study showed that vibrations of 2 to >10 times normal machine vibrations could occur from unbalanced moving machine parts or bearing damage. Their study concentrated on spindles, but logically, if any moving machine part is worn enough or damaged to the point of creating "extra-normal movement" of the part and anything attached to it, vibration will likely increase significantly.

How high a shock rating and vibration rating is enough for moving parts? Based on the research we reviewed as well as the decades of product motion design experience from Novotechnik’s engineers, specifying product with at least 50 g shock and 10 g vibration should serve you well.

Sources:

https://www.machinedyn.com/docs/machine_vibration_tutorial.pdf

https://accendoreliability.com/basics-vibration-shock/

https://reliabilityweb.com/articles/entry/standardization_of_absolute_vibration_level_and_damage_factors/

|

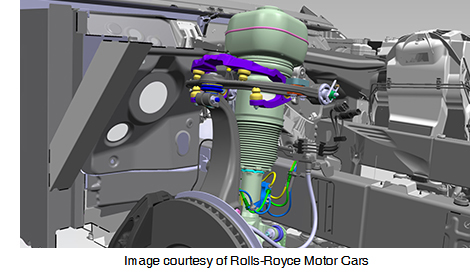

If you live in the northeastern United States or an area with similarly perpetually under-maintained roadways, imagine driving without having to feel the bumps at all. Engineers working on the new Rolls-Royce Ghost combined several technologies to enable just such an experience.

If you live in the northeastern United States or an area with similarly perpetually under-maintained roadways, imagine driving without having to feel the bumps at all. Engineers working on the new Rolls-Royce Ghost combined several technologies to enable just such an experience.