|

In this issue: Featured video: To view newsletter in your browser click here. |

|

| Watch the video |

Circular Juice Bar Squeezes Juice and 3D Prints Cups From Oranges

|

See the video: |

When I first heard of it, I asked, "what is a circular juice bar, and why is its engineering notable?" The answer has two parts. First, it is a self-contained circular economy machine: manufacturing -> consumer use -> recycling. Second, it is a machine that demonstrates a practical use for 3D food printing. |

| When A Calibrated Potentiometer Is Needed (And How To Calibrate One) | ||

|

||

|

|

||

All Terrain Vehicle Controls All Terrain Vehicle Controls |

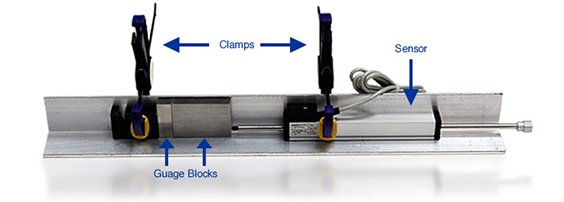

| A custom aftermarket all-terrain-vehicle manufacturer needed a reliable and accurate position sensor they could use for all position-related controls to allow their vehicles' steering, brakes, throttle, gearshift and other motion accessories to be controlled via a joystick for disabled persons, while a non-disabled person is seated next to the disabled driver ready to switch to stock controls and take over, if needed. |

|

| Novotechnik's TX2 met their requirements and was easily incorporated into each of their different vehicles' position control applications. Position sensing of steering, throttle, brake, gearshift and a moving ramp were achieved by utilizing right-sized length TX2 position sensors for each of the moving controls. The manufacturer elected to use a 0 to 10 V output for each sensor. Each sensor is wired to a custom control module to provide feedback on actual position. The vehicles joy sticks are also wired into the same control module that is programmed to compare joystick position with control positions for steering left or right as well as throttle and brakes by moving the joystick forward or back. Click here for more information on the TX2 Series sensor product used in this application. |

|

Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor |