|

In this issue: Featured video: To view newsletter in your browser click here. |

|

| Watch the video |

|

See tthe video: https://selfassemblylab.mit.edu/4d-printing/2018/1/5/oq15p04kjd3a6t6iylyst1q3yocwwb Source; https://sloanreview.mit.edu/article/transforming-manufacturing-and-supplychains-with-4d-printing/" |

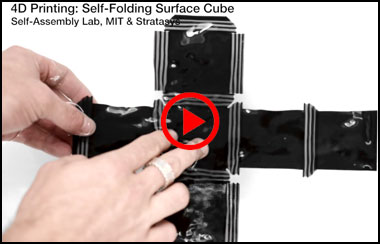

According to an MIT article, 4D printing could have the potential to transform manufacturing and supply chains. That’s quite a bold statement. So what is 4D printing? It’s a technology labeled as complex, but simply put, 4D printing is made using additive 3D printing technology using materials with different properties. Some of the materials are rigid and some ‘flexible’, so that can they can change when exposed to a planned-on external stimulus. This stimulus could be one that could adjust to fluctuations in temperature, water flow, and/or pressure. Pipe failure prevention and self-healing pipes are two examples an MIT article cites. The video shows a 4D object that self-assembles when exposed to a liquid. Imagine applications where an object can adapt in a controlled manner when an anticipated situation develops, or adapt to a change in environment. 4D printed bio-compatible materials as another example, could have great value in medicine. MIT article authors describe a couple more examples, “valves manufactured using hydrogel material, for example, were able to close automatically when the liquid flowing through them went above a threshold temperature, allowing for the control of water flow. 4D-printed pipes could also theoretically change their diameter according to flow volume or make other physical adaptations based on environmental criteria. In cases where normal pipes would break or crack due to increased flow, 4D-printed pipes could thus potentially adjust their size, leading to savings in maintenance, operating, and replacement costs as well.” |

| Shock and Vibration—Avoiding Problems From Them | |

|

First, let’s briefly define shock and vibration as well as their causes.

Shock is an impulse of energy applied to a machine or system. This causes sudden acceleration. Being an impulse, the duration of a shock event is short, but its amplitude Vibration can be sinusoidal or random. Frequently both are present. Vibrations also come in three categories: free, forced and damped. Free vibration could be described as occurring when a machine is idling without any issues and without loads. Forced vibration occurs when a time-dependent force is introduced into the system, like a periodic load for example. Damped vibration occurs when vibration energy is reduced by resisting forces like shock absorbers or machine mounts. In a machine, shock and vibration can be introduced by many different causes including gear wear, metal fatigue damage, moving machine parts at end-of-range direction changes, electro-mechanical parts, loosening of assembled-machine-parts and many more. According to sources of research, gearboxes, compressors, electric motors, fans, pumps, and blowers can create vibration in the range of 0.2 to 15 g of overall peak acceleration from 0 to 5,000 Hz.

|

Research from another source determined that a “damage factor” can be reliably used to predict future machine failure instead of conventional vibration monitoring. This study showed that vibrations of 2 to >10 times normal machine vibrations could occur from unbalanced moving machine parts or bearing damage. Their study concentrated on spindles, but logically, if any moving machine part is worn enough or damaged to the point of creating ‘extra-normal movement’ of the part and anything attached to it, vibration will likely increase significantly.

So given all this how can a machine designer avoid or limit future problems from shock and vibration? Obviously machine vibration damping products can be part of the design, and by also specifying individual parts that are in-motion to have sufficiently high shock and vibration ratings, many premature part failures can be avoided. How high a shock rating and vibration rating is enough for moving parts? Based on the research we reviewed as well as the decades of product motion design experience from Novotechnik’s engineers, specifying product with at least 50 g shock and 10 g vibration should serve you well. |

| Sources: https://www.machinedyn.com/docs/machine_vibration_tutorial.pdf https://accendoreliability.com/basics-vibration-shock/ https://reliabilityweb.com/articles/entry/standardization_of_absolute_vibration_level_and_damage_factors/ |

|

|

|

|

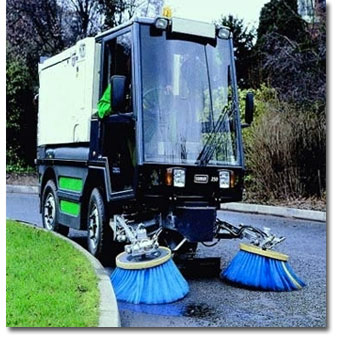

Four Wheel Steering Control Four Wheel Steering Control |

Road sweepers have to be able to maneuver between parked cars, in-street signage like “stop for pedestrians” signs, road works and a wide variety of other obstructions. Four wheel steering reduces the turning radius of this type of vehicle and offers road sweeper manufacturers real benefits as selling features for their vehicles. Road sweepers have to be able to maneuver between parked cars, in-street signage like “stop for pedestrians” signs, road works and a wide variety of other obstructions. Four wheel steering reduces the turning radius of this type of vehicle and offers road sweeper manufacturers real benefits as selling features for their vehicles.

Two SP2800 rotary angle sensors are fitted to each vehicle. They are fitted directly to the Kingpins of one front wheel and one rear wheel. When the driver turns the steering wheel a microcomputer sends a signal to a controller that adjusts actuators for the relative front / rear wheel angles to provide optimum performance—especially while rounding a curve in the road or maneuvering around an obstruction. It relies on the output signal from the SP2800's for the angle data. |

|

If you have a question about position sensors for your specific application, Novotechnik engineers would be glad to speak with you. Contact us at Email Novotechnik [email protected] or call 800-667-7492. Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor [email protected] |