|

In this issue: Featured video: Ossia™ Cota’s™ wireless power To view newsletter in your browser click here. |

|

| See the Cota wireless power video |

|

According to Ossia, their power platform, called Cota, uses radio frequency to deliver wireless power through the air over a room-sized distance without cables, batteries, line-of-sight, or charging mats. Applications include industrial, smartphones, batteries, automotive sensors, wearables, and smartphones. The Cota platform has three main components: The Cota—Transmitter, — Receiver and —Cloud. Ossia’s receiver chip is 5 mm square and can receive up to 4 watts of incoming radio frequency (RF) power from as many as four antennas simultaneously and from over 15 feet away. |

|

| See the video: https://www.youtube.com/watch?v=HEfPgx51cas&feature=youtu.be | |

| Sources: http://www.nibletz.com/events/ces-2018/ossia-cota, http://www.ossia.com, https://www.computerworld.com/article/3235176/mobile-wireless/wireless-charging-explained-what-is-it-andhow-does-it-work.html | |

| In many applications, engineers that use linear position sensors can gain development time, part cost savings and be able to deliver needed application product features by being able to easily program some key attributes into linear position sensors—right on the sensor. This Tech Tip article describes the benefits and how they are achieved.

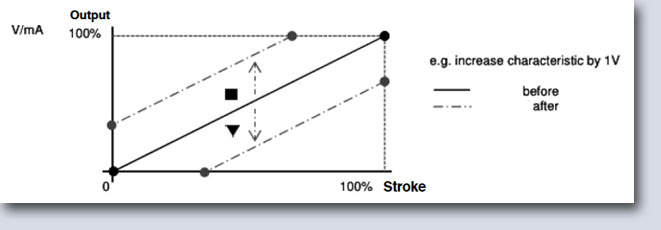

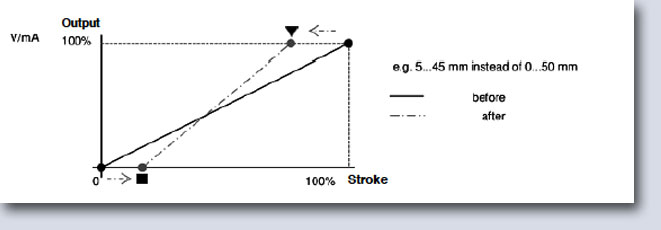

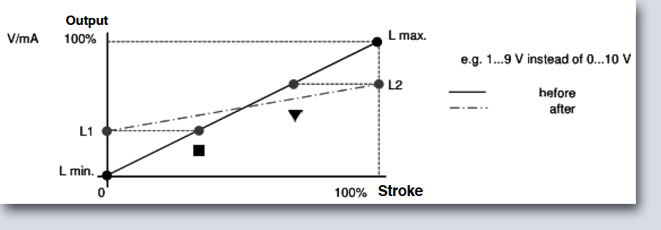

Several useful parameters can be programmed into linear position sensors including electrical measurement range, slope, position for minimum output voltage/current, position for maximum output voltage/current and offset. The electrical measurement range sets both the minimum and maximum positions for which a change in output signal will occur. By setting these at values other than zero and full scale, applications that require a slope other than 1:1 could be accommodated. It could also be used to limit the output range to occur over a smaller portion of the travel range at specific starting and ending distances from physical end-points. A negative slope might also be programmed so that the output value decreases as the stroke length increases. Programming an offset would allow an output value other than 0 to represent a position of 0 inches.

With all this you’d image that there must be some benefits to using this technology in an - In high noise environments, maximum noise rejection can be achieved by applying the entire output range to the actual travel length your application requires rather than the entire stroke length of the position sensor.

Optimizing sensor range for your application. - By programming an offset, a sensor can be adjusted in seconds for deviations or tolerances in mounting the physical sensor without moving the sensor. - Output voltage can be set to either a minimum or maximum threshold, say 1.0 V (L1) on the low end and 9.0 V (L2) on the high. So by programming limits to the output of the sensor, it can serve as an error detector. If the output is limited in this manner, and voltage falls outside of the set range, a cable fault - open or short - is likely occurring and a process monitor could be set to indicate a fault under these circumstances.

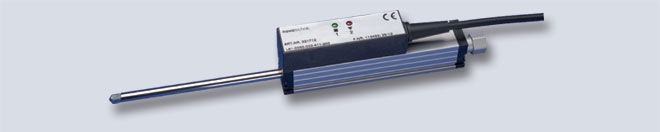

- By programming a sensor you can also eliminate the need for programmable process monitor in some applications and use an inexpensive readout that simply displays values instead. To sum up, new technology combines the benefits of non-contact linear position sensing with some essential programmability of a programmable controller all in a relatively small sensor package. This technology can help engineers in a number of applications including those where costs and/or development time can be saved with all control functions needed handled by the position sensor, applications requiring high accuracy over a small distance and applications with noisy environments. An implementation of this technology is seen in Novotechnik’s LS1 Series of position sensors, shown here. On these devices programming is accomplished by pressing the dual purpose LEDs/buttons according to published guidelines and observing the status of the LEDs. The square and triangle below the LEDs serve as a visual guide as to differentiate the LED/buttons in communicating which button to press.

A few of the applications that are using this technology are material handling equipment, crimping machines and position sensors for linear actuators. To view Novotechnik’s implementation of this technology including programming examples with charts, view Programmable Linear Position Sensors White Paper at: http://www.novotechnik.com/news/whitepapers.html

|

|

If you have a question about position sensors for your specific application, Novotechnik engineers would be glad to speak with you. Contact us at Email Novotechnik [email protected] or call 800-667-7492. Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor [email protected] |