|

This issue’s articles: Featured video: Immersit 4D motion To view newsletter in your browser click here. |

|

|

Their product includes a control hub and four motion devices — with one electric motor-driven “base” placed under each leg of a couch or chair. Together they move the seated viewer forward, back, up, down and sideways. |

|

|

How it works |

|

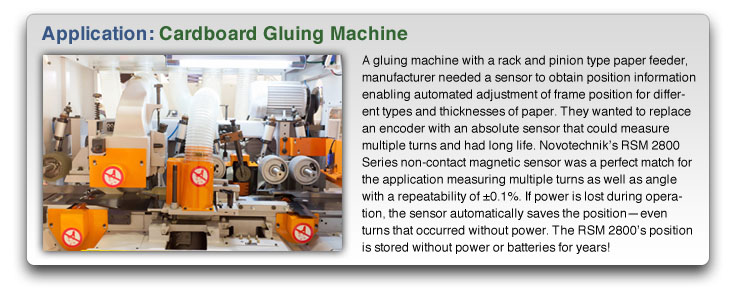

| There are applications that are better suited to using a shafted rotary position sensor and others where a touchless (free-floating magnetic) one is a better choice. This tip presents several application situations and which type of sensor is preferred for that application as a guide to help with selection in general.

Applications that benefit from use of a shaft-type sensor

- Applications where the sensor needs to be part of a gear box or geared actuator and has a gear on its shaft. - When replacing a contacting potentiometer type or RVDT-type sensor that had a shaft of same size. - When the measurement site is very far from where the sensor can be mounted due to design considerations such as extreme heat. Applications that benefit from a touchless sensor - Applications where an angle measurement is made through the enclosure or machine wall. - Applications seeking an IP69K sealed sensor - When no sensor wear is desired

- When a small radial misalignment of the applications rotating shaft may occur Touchless sensor benefits - Completely enclosed magnet and sensor for superior sealing properties - No wear because no contact - Radial and axial misalignment do not necessarily have to be compensated with expensive couplings - Vibration from drive shaft / magnet marker does not get transferred to sensor providing maximum robustness - Flexible mounting of sensor on front or on back of a mounting plate - Can measure through non-magnetic walls <1/4”. |

|

Feed Forward: An Overview For Better System Response

|

||||

If If you have a question about position sensors for your specific application, Novotechnik engineers would be glad to speak with you. Contact us at Email Novotechnik [email protected] or call 800-667-7492.

Please email suggestions for technical subjects you would like to suggest for this newsletter to this link: Newsletter Editor [email protected]